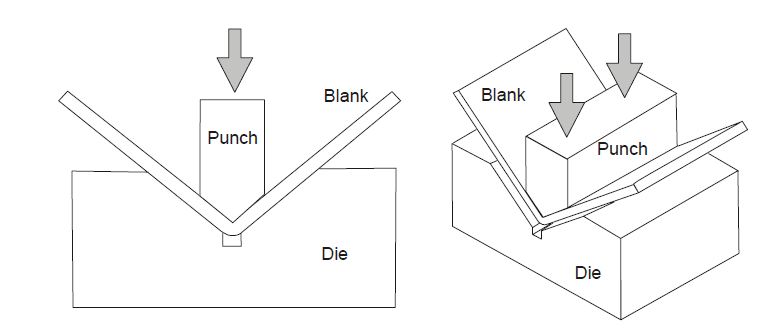

V-bending is ideal for simple shapes and produces precise and consistent bends. However, it's not suitable for complex shapes or tight radii bends.

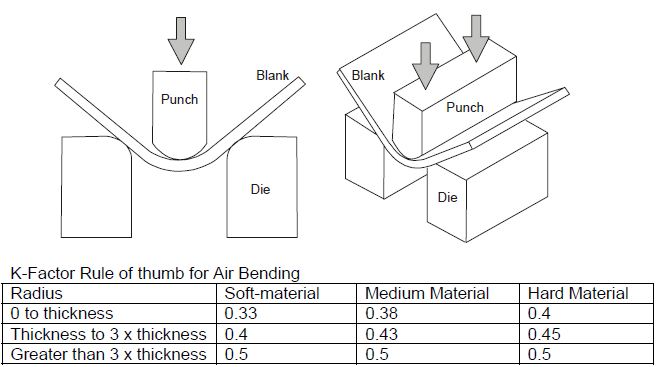

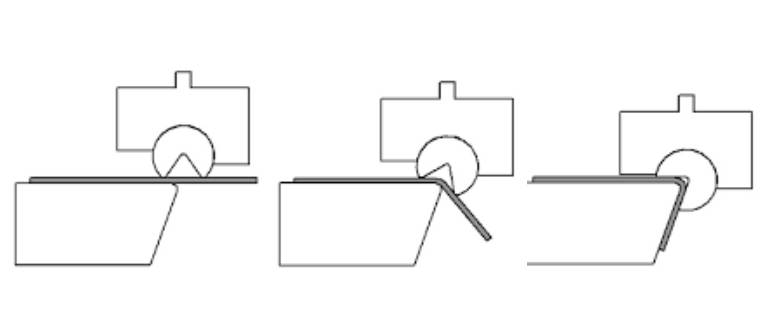

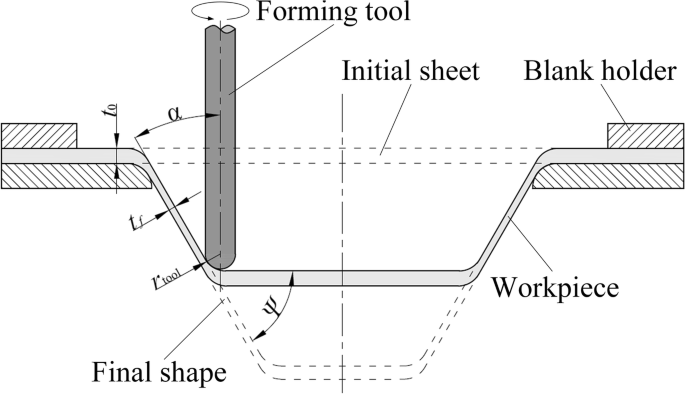

Air bending is versatile and can produce a range of shapes and angles. However, it requires precise calculations and adjustments to achieve accurate bends.

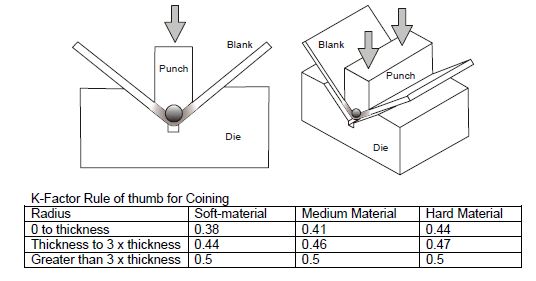

Coining is a method that involves creating a bend angle by compressing the metal sheet between two dies. This method produces high-quality, precise bends, but it's a slower process and requires more tooling compared to air bending.

Stretch bending is suitable for producing large, complex shapes and tight radii bends but requires specialized equipment and expertise to control the stretching and bending process.

Conclusion

Bending sheet metal requires skill, precision, and attention to detail. By choosing the right tool, calculating the bend allowance and deduction, and applying the appropriate bending technique, you can achieve flawless bends in sheet metal. Follow these essential tips for precise and accurate bends, and you will be on your way to becoming a skilled metalworker.

Try our professional Sheet Metal Fabrication Service today.

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China Tel/Whatsapp : +86-1377-0661-937

Tel/Whatsapp : +86-1377-0661-937 Email : sales@comelycnc.com

Email : sales@comelycnc.com