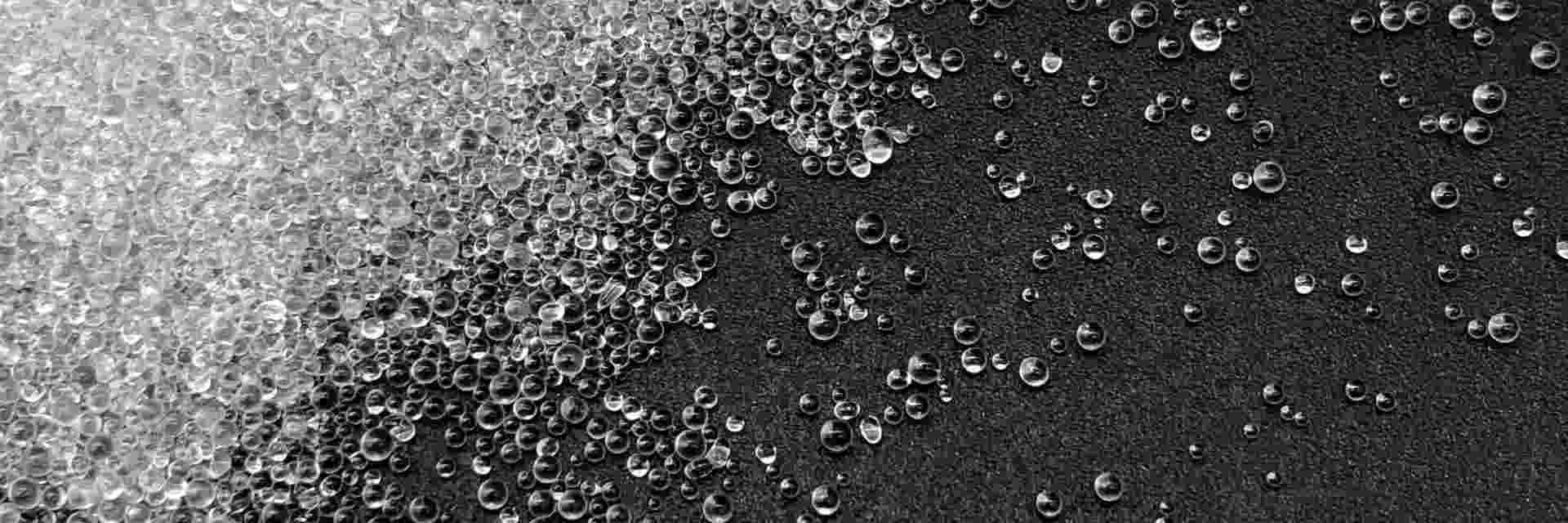

Bead blasting is a process that uses tiny glass or ceramic beads to remove surface impurities from metal, plastic, or other materials. The beads are shot at high speeds, using compressed air or a blasting wheel, to clean, smooth, and shape the surface. This process is commonly used to remove paint, rust, and other contaminants from surfaces that will be painted, coated, or plated.

There are several types of bead blasting, each with its own specific benefits and applications.

This process uses small, spherical glass beads to remove surface impurities. Glass bead blasting is ideal for creating a smooth, uniform finish on surfaces such as aluminum, brass, or stainless steel. It is commonly used to prepare surfaces for painting or powder coating.

Ceramic bead blasting uses small, spherical beads made from zirconia or aluminum oxide. This process is ideal for removing surface impurities from materials such as titanium, magnesium, or composites. Ceramic bead blasting is often used in aerospace and defense industries.

This process uses small, spherical steel beads to remove surface impurities. Steel shot blasting is commonly used to prepare surfaces for coating or plating. It is also used to clean large structural steel components such as bridges and buildings.

Applications of Bead Blasting Finish

In conclusion, bead blasting is an essential process for achieving high-quality surface finishes. By using the right type of beads and equipment, you can achieve a uniform surface finish that will last for years to come. At Comely CNC, we offer high-quality bead blasting services that are designed to meet the needs of any project. Contact us today to learn more about how we can help you achieve the perfect surface finish for your project.

Get A Quote for your bead blasting service!

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China Tel/Whatsapp : +86-1377-0661-937

Tel/Whatsapp : +86-1377-0661-937 Email : sales@comelycnc.com

Email : sales@comelycnc.com