what are you looking for?

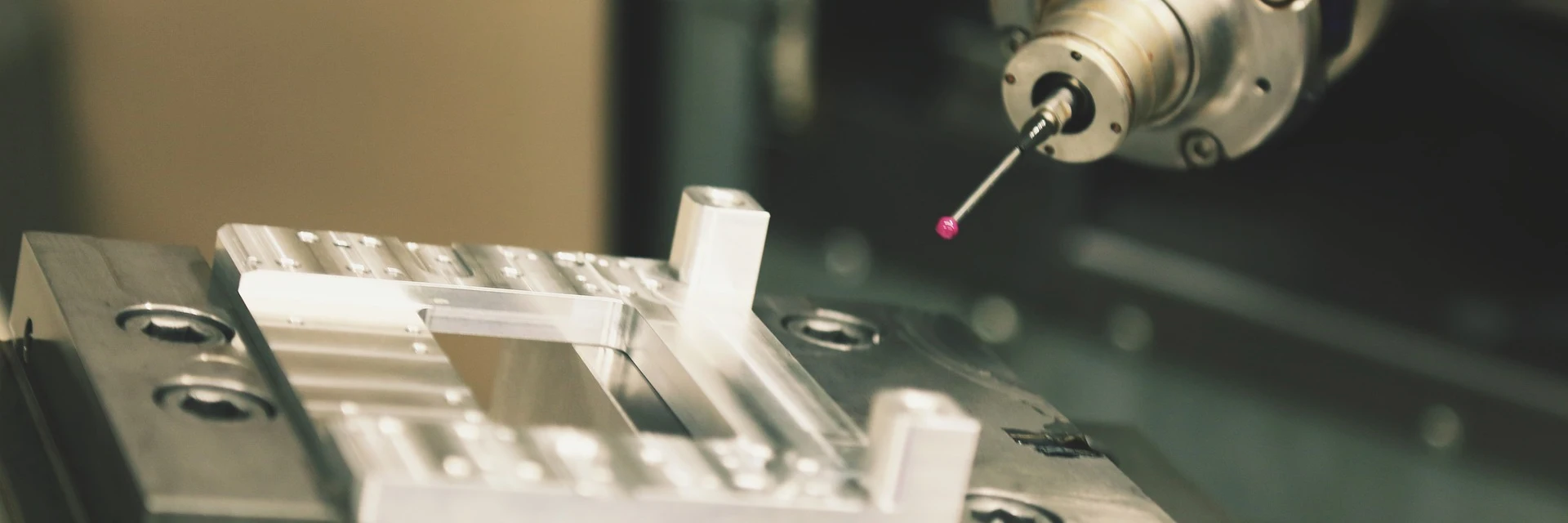

While CNC machining can be cost-effective for large production runs, it may not be the most economical option for small-scale projects due to tooling and setup costs.

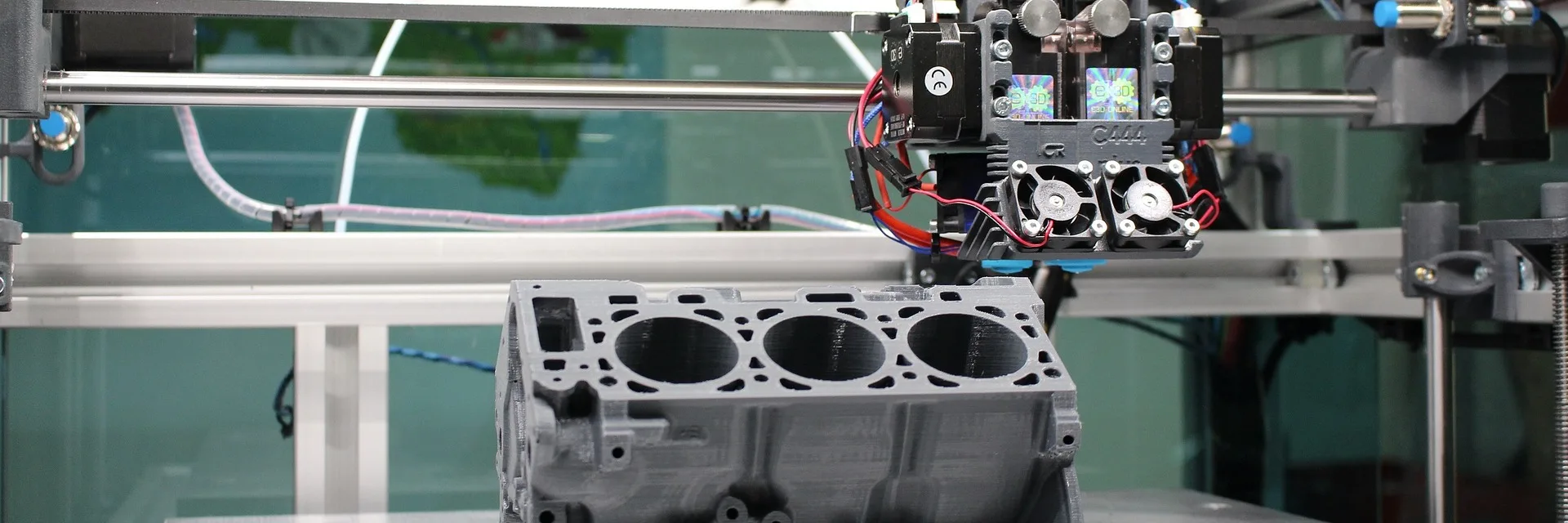

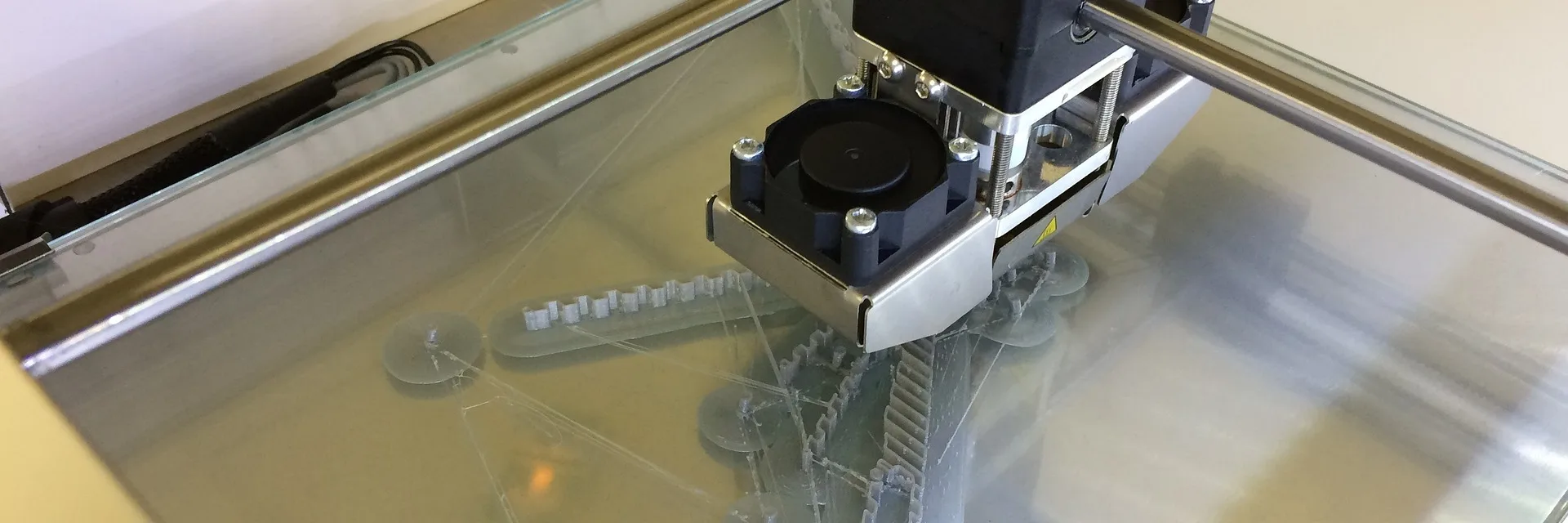

3D Printing, or additive manufacturing, is a relatively newer technology that has gained immense popularity in recent years. Instead of removing material, 3D printing builds objects layer by layer from a digital design. Let's explore the defining characteristics of 3D printing:

Compared to CNC machining, 3D printing tends to have rougher surface finishes and wider tolerances, which may not be suitable for applications demanding high precision.

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China Tel/Whatsapp : +86-1377-0661-937

Tel/Whatsapp : +86-1377-0661-937 Email : sales@comelycnc.com

Email : sales@comelycnc.com