CNC Machining, on the other hand, is a subtractive manufacturing method. It involves carving out a part from a solid block of metal using precision-controlled machines.

CNC Machining is known for its remarkable precision and ability to meet tight tolerances, making it a preferred choice for industries where precision is non-negotiable.

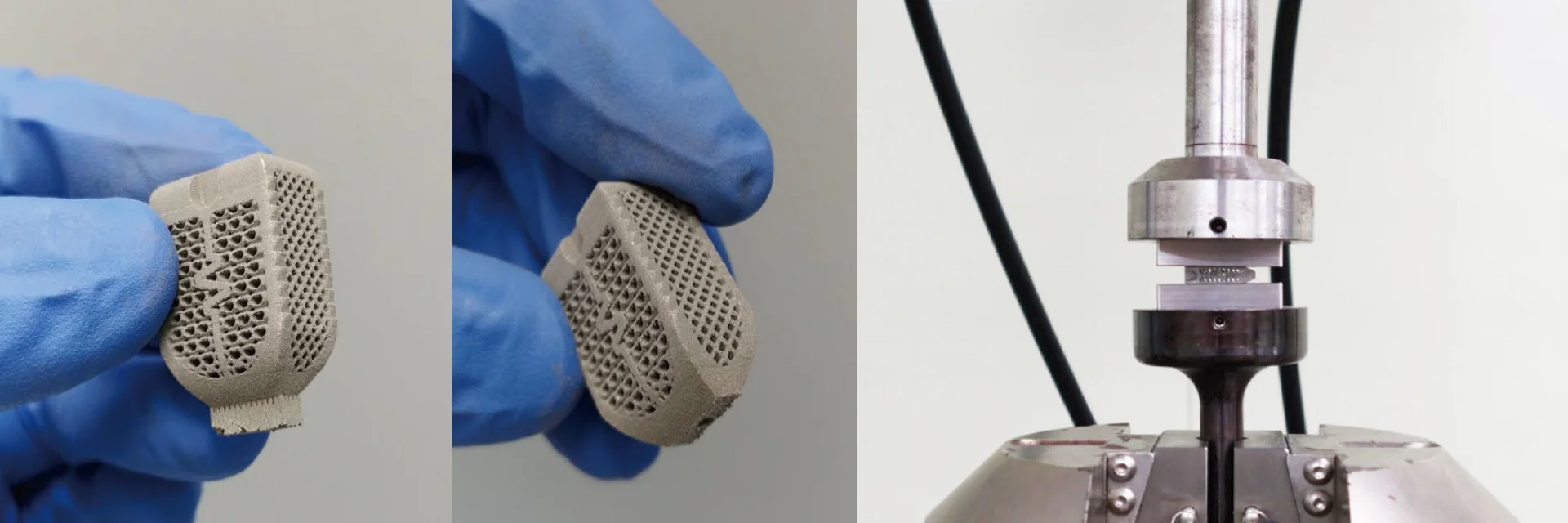

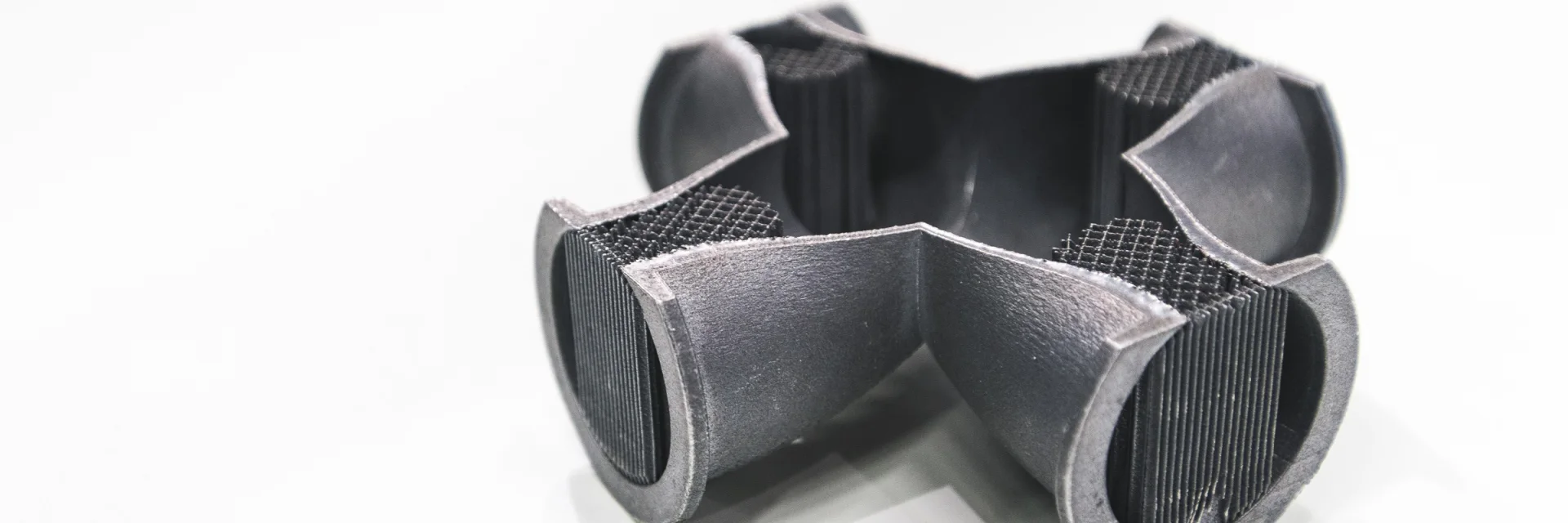

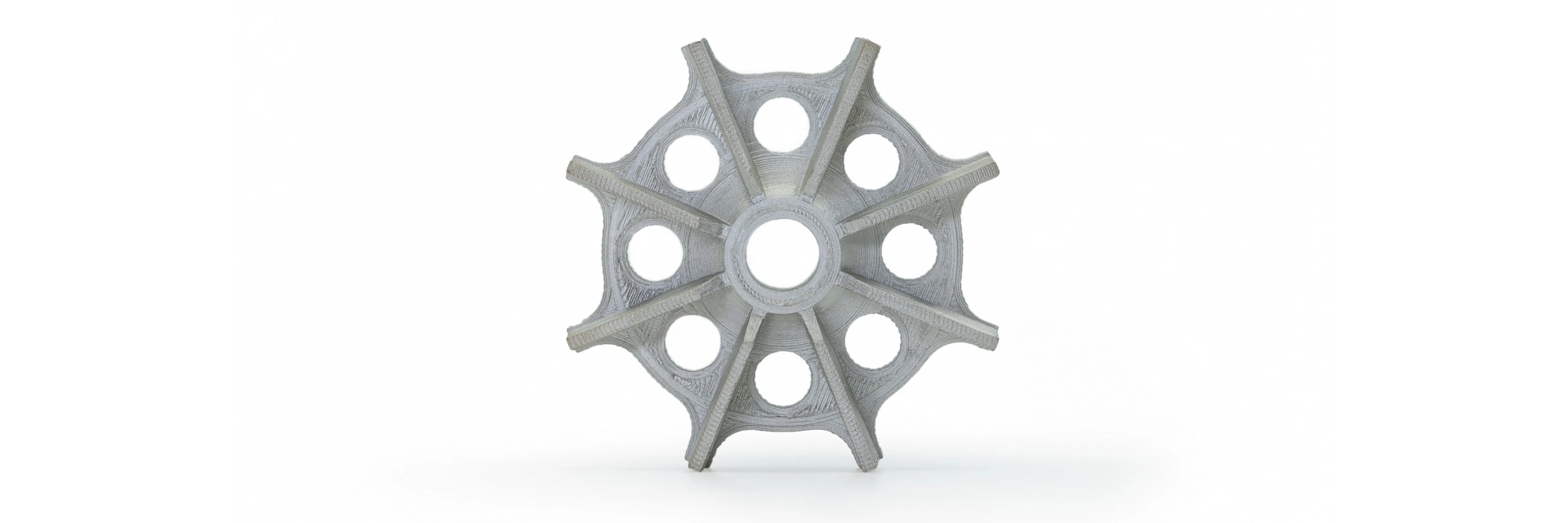

As a leader in CNC Machining, Comely CNC understands the significance of keeping pace with the latest advancements in manufacturing technology. Our expertise extends beyond traditional CNC Machining, as we also offer cutting-edge Metal 3D Printing services. This means that we're uniquely positioned to provide our clients with a versatile array of manufacturing solutions. Whether you require the precision and efficiency of CNC Machining or the intricacy and customization of Metal 3D Printing, Comely CNC is your trusted partner for top-notch manufacturing services. We believe in empowering your vision through the best of both worlds, ensuring you receive the highest quality components tailored to your specific needs. Check here for a Quote.

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China Tel/Whatsapp : +86-1377-0661-937

Tel/Whatsapp : +86-1377-0661-937 Email : sales@comelycnc.com

Email : sales@comelycnc.com