Welcome to our comprehensive guide on anodizing aluminum parts. In this article, we will provide you with all the necessary information and step-by-step instructions to help you understand and implement the process of anodizing aluminum parts effectively. Whether you are a beginner or an experienced individual in the world of metalworking, this guide aims to assist you in achieving the best results when anodizing aluminum.

What is Anodization?

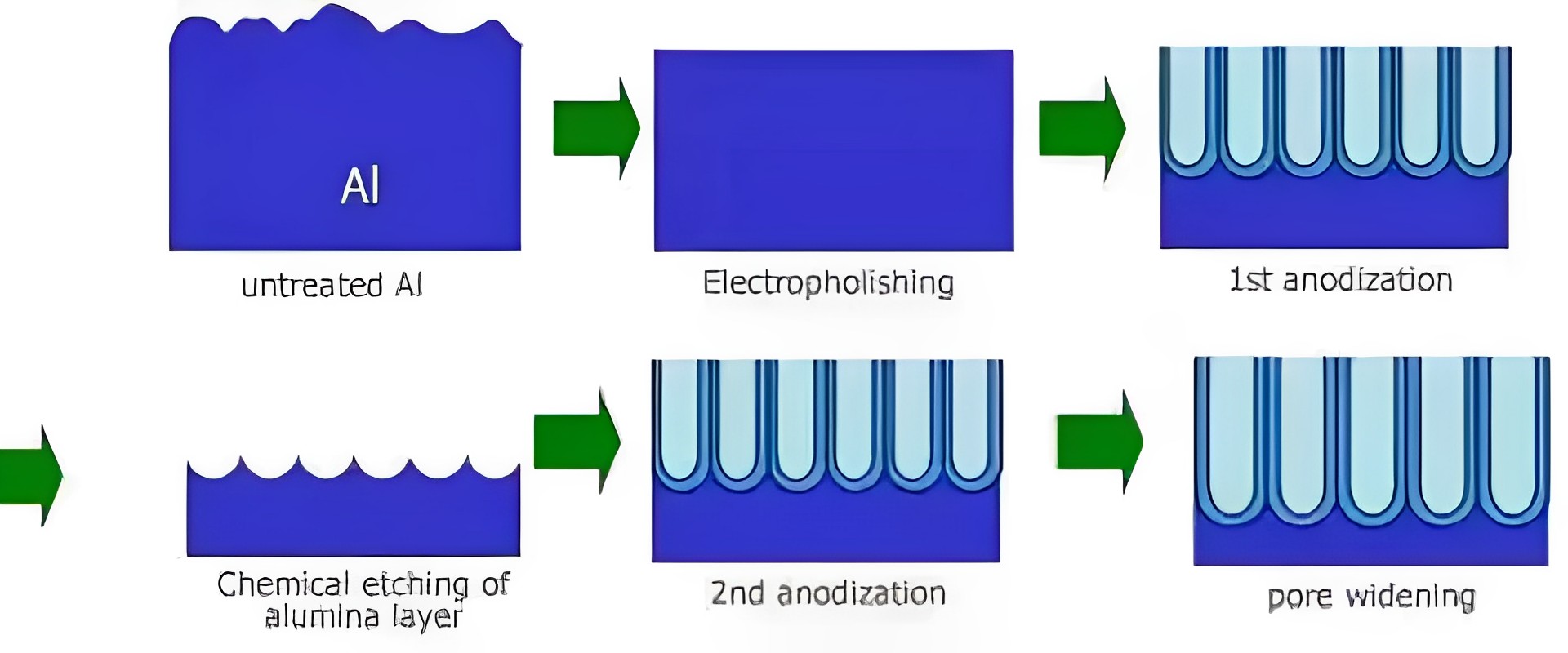

Anodization is an electrochemical process that enhances the surface properties of aluminum, making it more durable, corrosion-resistant, and aesthetically appealing. It involves creating an oxide layer on the surface of aluminum by immersing it in an electrolytic bath and applying an electric current. This oxide layer provides several benefits, including improved hardness, increased wear resistance, and better paint and other coatings adhesion.

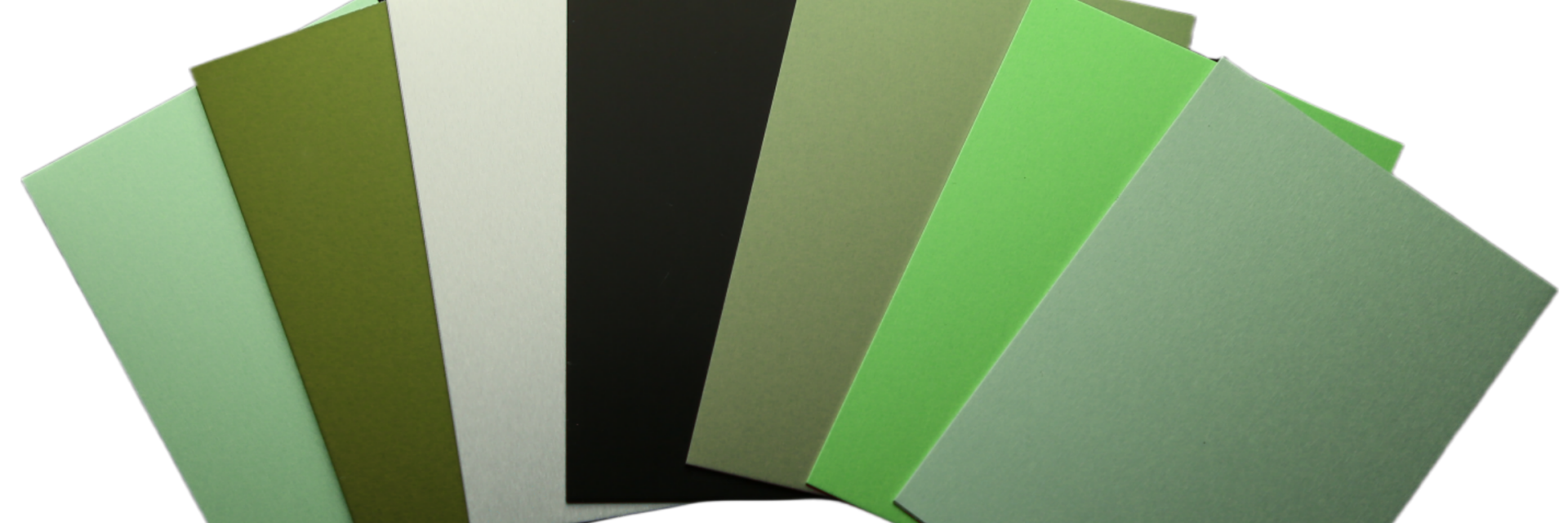

Anodizing aluminum offers a wide range of color options, allowing you to achieve the desired aesthetic appeal for your projects. Through the anodization process, the surface can be dyed to various shades, providing versatility in design while maintaining the natural metallic appearance of the aluminum.

Step 1: Preparation

Before beginning the anodization process, it is crucial to prepare the aluminum parts properly. Start by cleaning the surface thoroughly to remove any dirt, grease, or contaminants. This can be achieved using a mild detergent, warm water, and a soft cloth or sponge. Rinse the parts thoroughly and ensure they are completely dry before proceeding.

Section 3: Tips for Successful Anodization

Conclusion

In conclusion, anodizing aluminum parts is a highly beneficial process that enhances their durability, corrosion resistance, and visual appeal. By following the steps outlined in this guide and paying attention to crucial details, you can achieve outstanding results in anodizing. Remember to prioritize safety, prepare the surface meticulously, and maintain control over the voltage and current during the process. With the right knowledge and practice, you can successfully anodize aluminum parts for a wide range of applications.

At Comely CNC, we pride ourselves on our expertise in CNC machining and our commitment to providing high-quality services. We hope this comprehensive guide has provided valuable insights and techniques to help you outrank your competitors and make informed decisions regarding CNC machining cost estimation.

For further assistance or to explore our range of CNC machining services, please contact us. We look forward to working with you to meet your CNC machining needs.

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China Tel/Whatsapp : +86-1377-0661-937

Tel/Whatsapp : +86-1377-0661-937 Email : sales@comelycnc.com

Email : sales@comelycnc.com