Laser engraving has emerged as a groundbreaking technology that has revolutionized the world of precision marking and customization. In this comprehensive article, we will delve deep into the fascinating world of laser engraving, exploring its intricate workings and diverse applications. With a profound understanding of this cutting-edge process, you will be better equipped to leverage its potential for your specific needs.

1. Understanding Laser Engraving

At its core, laser engraving is an advanced technique that employs a highly focused laser beam to etch or mark various materials. The process involves the use of a computer-controlled laser, which emits a powerful beam of light to remove material from the surface, leaving behind intricate designs, texts, or patterns. The precision and versatility of laser engraving have made it a preferred choice across industries, ranging from manufacturing and jewelry to art and personalization.

2. How Laser Engraving Works

2.1. The Laser Source

The heart of the laser engraving process lies in the laser source itself. There are several types of lasers used in engraving, such as CO2, fiber, and Nd:YAG lasers. Each laser type offers distinct characteristics, making them suitable for different materials and applications.

2.2. Focusing the Laser Beam

Once the laser beam is generated, it is carefully directed through lenses or mirrors to achieve pinpoint accuracy. The focused laser beam is crucial in ensuring precise and fine engravings on the material's surface.

2.3. Material Interaction

As the focused laser beam strikes the material, it imparts a controlled amount of energy to the surface. This energy rapidly heats and vaporizes the material, creating the desired engravings or markings. The depth of the engraving can be adjusted based on the number of laser passes and the power settings.

2.4. Different Engraving Techniques

Laser engraving encompasses various techniques, each suited for different outcomes:

2.4.1. Vector Engraving

Vector engraving involves following the outline of a design with continuous laser movements, producing precise, clean-cut lines. This technique is ideal for intricate text and logos.

2.4.2. Raster Engraving

Raster engraving utilizes a scanning motion to create patterns and gradients, similar to the action of an inkjet printer. This technique is commonly used for images and shading effects.

2.4.3. Deep Engraving

Deep engraving involves multiple passes of the laser to create deeper grooves or cavities in the material, making it suitable for applications requiring depth and dimensionality.

3. Applications of Laser Engraving

The versatility of laser engraving is reflected in its broad range of applications across industries. Some prominent uses include:

3.1. Industrial Manufacturing

In the industrial sector, laser engraving is widely employed for marking and branding products, adding essential information like serial numbers, barcodes, and logos. This ensures product traceability and enhances brand visibility.

3.2. Personalization and Giftware

Laser engraving has become a popular choice for personalized gifts and keepsakes. From engraving names on jewelry to customizing trophies and plaques, this process adds a touch of sentimentality to special occasions.

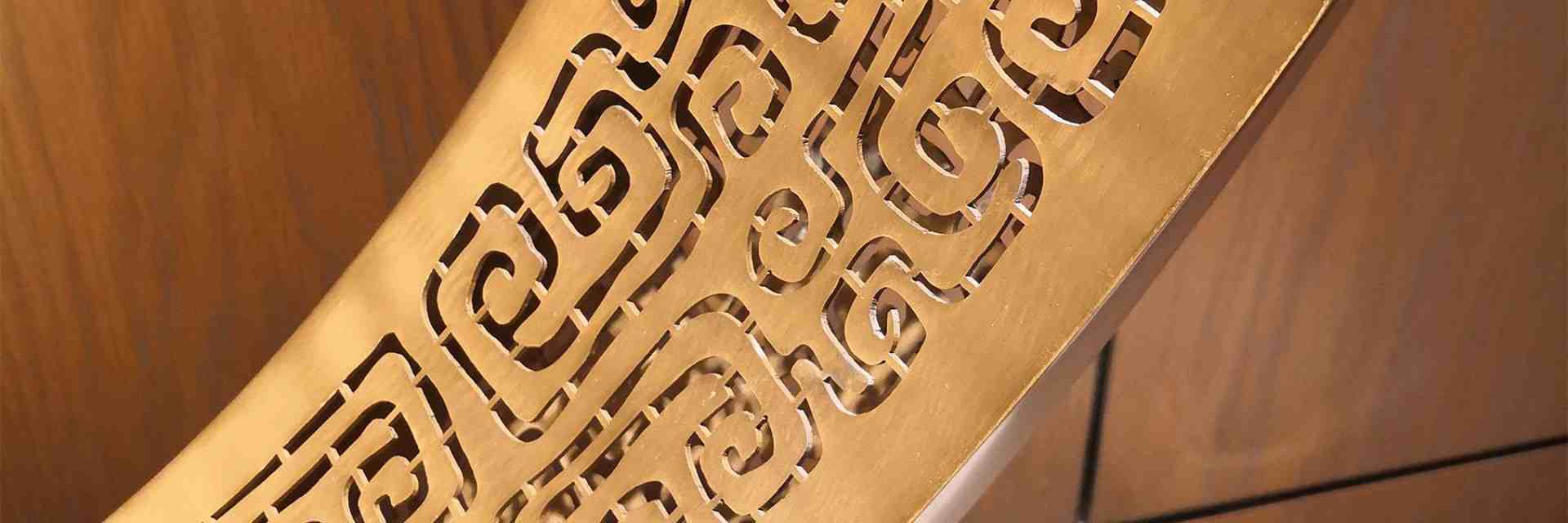

3.3. Architecture and Signage

Architects and designers use laser engraving to create intricate patterns and designs on various materials like wood, acrylic, and metal. Laser-engraved signage and architectural details offer a unique and elegant appearance.

3.4. Medical Devices and Instruments

The medical industry relies on laser engraving to mark surgical instruments, implants, and medical devices. The permanent and legible markings facilitate easy identification and tracking during medical procedures.

3.5. Art and Creativity

Artists and artisans leverage laser engraving to push the boundaries of creativity. From laser-cut stencils to engraved sculptures, this technology enables intricate and precise artwork on various media.

4. Advantages of Laser Engraving

4.1. Unmatched Precision

Laser engraving offers unparalleled precision and accuracy, allowing for intricate details and fine lines with minimal tolerances.

4.2. Versatility

The ability to engrave on a wide range of materials, from metals and plastics to wood and glass, makes laser engraving highly versatile.

4.3. Non-Contact Process

As a non-contact process, laser engraving eliminates the risk of surface damage and reduces wear on the equipment, ensuring a longer lifespan.

4.4. High-Speed Marking

Laser engraving is a swift process, capable of marking thousands of items per hour, making it ideal for mass production.

4.5. Durability and Permanence

The engravings created by lasers are highly durable, resistant to fading, and can withstand harsh environments, ensuring longevity.

5. Conclusion

In conclusion, laser engraving represents the epitome of precision and innovation in the realm of marking and customization. From its advanced workings to its diverse applications, this cutting-edge technology has earned its place in various industries worldwide.

With a comprehensive understanding of how laser engraving works and its multitude of benefits, you can harness its potential to elevate your projects and products to new heights. Whether you seek to leave an indelible mark on your industrial products or add a personalized touch to gifts and keepsakes, laser engraving offers limitless possibilities.

To explore more about how you can leverage laser engraving for your specific needs, contact us at Comely CNC. As industry-leading experts in CNC machining, laser cutting, and engraving services, we are dedicated to providing top-tier solutions that surpass expectations. Embrace the precision, creativity, and durability of laser engraving with Comely CNC today. Request A Quote!

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China Tel/Whatsapp : +86-1377-0661-937

Tel/Whatsapp : +86-1377-0661-937 Email : sales@comelycnc.com

Email : sales@comelycnc.com